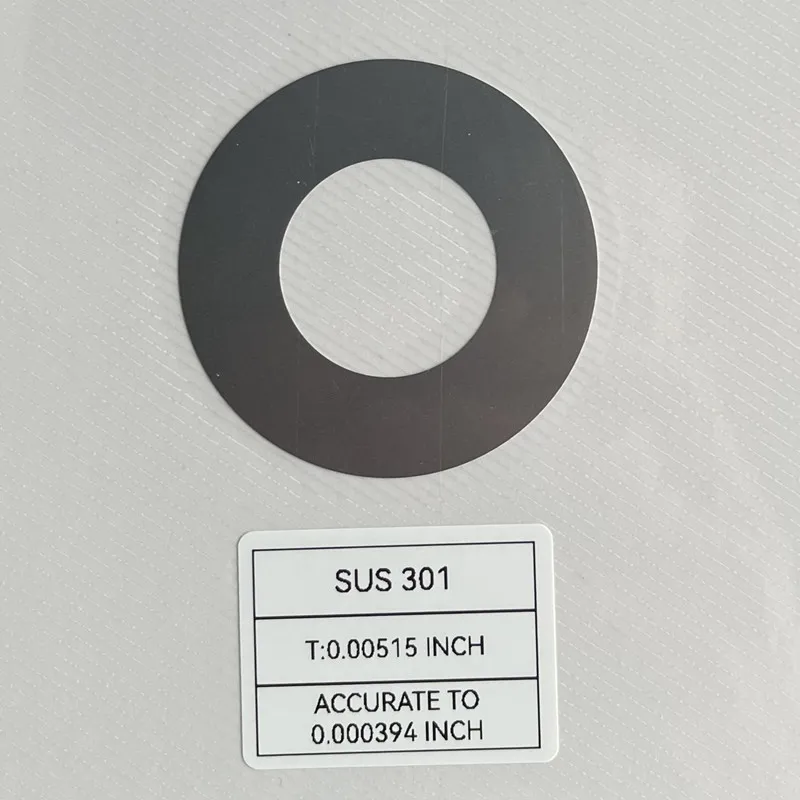

Shims Spacers And Washers Laser Cutting Service

Ultra-high Precision Custom Laser Cutting Service Shims Spacers And Washers OEM/ODM

We specialize in laser cutting and can cut stainless steel, copper, aluminum, titanium, nickel, molybdenum, platinum, tungsten, silicon steel, polycrystalline silicon wafers, ceramics, etc.Precision metal laser cutting services typically offer high accuracy and intricacy in cutting various types of metals with a thickness as thin as 0.06 millimeters (mm). This level of precision is achieved using advanced laser cutting technology, which utilizes focused laser beams to cut through metal sheets or plates with exceptional accuracy and minimal material waste.

Ultra-high precision custom laser cutting service specializing in shims, spacers, and washers offers advanced capabilities tailored to the exacting requirements of these components. Microscopic Precision: Ultra-high precision laser cutting ensures microscopic accuracy and tight tolerances, essential for creating shims, spacers, and washers with precise dimensions and thicknesses. This level of precision ensures optimal fitment and performance in various applications. Customization for OEM/ODM Solutions: The service specializes in providing OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) solutions, allowing for customization of shims, spacers, and washers to meet specific customer requirements. This includes custom shapes, sizes, thicknesses, hole patterns, and material selections. Wide Range of Materials: The service can work with a wide range of materials suitable for shims, spacers, and washers, including metals (such as stainless steel, aluminum, brass, copper, and various alloys) and non-metallic materials (such as plastics, rubber, and composites). They have expertise in selecting the optimal material based on the application's requirements. Advanced Laser Cutting Technology: The service utilizes advanced laser cutting technology, including ultra-high precision laser systems with sophisticated control systems.

316 stainless steel plate

304 stainless Steel Plate Lower cost than traditional machining High precision and better repeatability from part to part. Perfect 90 degrees cuts. Cleaner surface that does not require secondary deburring Smooth aperture sidewalls No stress from physical tools Smaller feature sizes Reduced material waste Tighter tolerances Minimal heat affected areas PREFERRED DATA FORMATS There are many forms of acceptable data. The following is a list of data formats that are acceptable for laser design files to be submitted in: Gerber, DXF, HP-GL, and HP-GL2 are the primary formats accepted. Please note that it is a good idea to include a PDF drawing of the data provided for reference. We can always send a check plot before proceeding to

|

stainless steel |

Thickness |

Processing accuracy |

Minimum circular hole |

Minimum slit |

Minimum square hole |

|

0.03~0.6mm |

0.01mm |

0.02mm |

0.02mm |

0.03 * 0.06mm |

|

|

0.7mm~3.0mm |

0.02~0.03mm |

0.02mm |

0.02mm |

0.03 * 0.06mm |

|

|

3.0~6.0mm |

0.03~0.05mm |

0.02mm |

0.02mm |

0.03 * 0.06mm |

PRODUCT SPECIFICATIONS

|

No |

Item |

Data |

||

|

1 |

Processing technology |

Magnetic steel sheet processing |

||

|

2 |

Processing type |

Hollow processing |

||

|

3 |

Minimum square hole |

0.01 * 0.06mm |

||

|

4 |

Processing accuracy |

0.003mm |

||

|

5 |

Processing equipment |

laser cutting machine |

||

|

6 |

Materials |

stainless steel, galvanized sheet, copper, iron, aluminum, zinc, aluminum alloy, etc |

||

|

7 |

Number of machines |

16 sets |

||

|

8 |

Processing capability |

20000/day |