618-NC 6T automatic riveting machine

6T Automatic Hydraulic-pneumatic Riveting Machine Anti-pressure For Sheet Metal Precision Processing Nuts and Bolts

57KN Ram Force 450mm Throat Depth PLC System Fastener Insertion Machine Fastener insertion machine. 57KN Ram Force: This indicates the force exerted by the ram (the part of the machine responsible for inserting the fastener) during operation. In this case, it's 57 kilonewtons, which is a measure of force. 18 inch (450mm) Throat Depth: Throat depth refers to the distance from the center of the fastener insertion point to the nearest vertical part of the machine, which determines how far the machine can reach into a workpiece. In this case, it has an 18-inch throat depth, or approximately 450 millimeters. PLC System: PLC stands for Programmable Logic Controller. It's a digital computer used for automation of electromechanical processes, such as controlling the operation of machinery. In the context of a fastener insertion machine, a PLC system would likely control the machine's operation, including the timing, speed, and force of the ram, as well as any other relevant functions. High Rigidity Integrated Processing Machine Body Structure The machine body design structure effectively enhances the rigidity of the frame, ensuring no vibration during riveting operations to guarantee riveting precision, significantly improving stability, and enhancing production efficiency and quality assurance. Anti-pressure Hand Safety Protection System Provides comprehensive protection for riveting conductive and non-conductive materials, greatly boosting operator confidence and efficiency. Pressure Control With a user-friendly interface and dedicated pressure testing and adjustment buttons, you can set the correct riveting pressure within five seconds, ensuring efficient production. The anti-pressure hand protection system maximizes equipment uptime. Pressure Holding Function and Stroke Adjustment Maintains a stable pressure over a certain time to overcome the elastic deformation of metal materials, preventing rivet loosening or detachment. The equipment is equipped with dedicated buttons for flexible adjustment of cylinder return height to meet various bending requirements. Total Riveting Count A counter on the control panel displays the total number of rivets, facilitating real-time monitoring and management of production efficiency, enhancing operational efficiency, optimizing production processes, and ensuring precise production planning and material management. Energy Saving and Environmental Protection Fully hydraulic drive reduces energy consumption by approximately 40% compared to pneumatic and hybrid pneumatic-hydraulic systems, significantly lowering operating costs. The machine operates at full load only during riveting, with energy consumption reduced to 15% during standby. This translation captures the essence of the provided text regarding the features and benefits of the automatic riveting machine, emphasizing its structural integrity, safety systems, control capabilities, efficiency, and environmental advantages.

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

618-NC Easy Operation Press Fastener Hydraulic Insertion Machine

|

No |

Drive System |

PLC |

||

|

1 |

Force |

3-57KN |

||

|

2 |

Throat Depth |

18in.( 450mm) |

||

|

3 |

Throat Height |

400mm |

||

|

4 |

Cylinder stroke |

200mm |

||

|

5 |

Electric Power |

380-400V 3PHASE 50HZ |

||

|

6 |

Applicable rivet types |

Nuts: S-M3-0/1/2 , S-M4-0/1/2 , S-M5-0/1/2 , S-M6-0/1/2 , S-M8-1/2 |

||

|

7 |

Drive mode |

Hydraulic system |

||

|

8 |

Hydraulic pump motor power |

2.25kw |

||

|

9 |

Equipment size |

Length*width*height = 1100mm*950mm* 2050mm |

||

|

10 |

equipment weight |

650kg |

||

|

11 |

Air pressure |

0.6 MPa |

||

|

12 |

Fuel tank capacity |

60L |

A fastener insertion machine is a piece of equipment used in manufacturing and assembly processes to automatically insert fasteners such as screws, bolts, rivets, or clips into workpieces. These machines are commonly used in industries such as automotive, aerospace, electronics, and construction. Fastener insertion machines come in various types and configurations, depending on the specific application and the type of fastener being used. Some common types include: Automatic Screwdriving Systems: These machines are designed to automatically drive screws into workpieces with high speed and precision. They often use a vibratory bowl feeder to orient and feed screws to the driving mechanism. Riveting Machines: Riveting machines are used to insert rivets into workpieces by deforming the rivet body to create a permanent joint. They can be pneumatic, hydraulic, or electrically powered, depending on the application. Nut Insertion Machines: Nut insertion machines are used to insert threaded nuts into workpieces, allowing for subsequent attachment of bolts or screws. Fastener insertion machines offer several advantages, including increased productivity, improved quality and consistency, reduced labor costs, and enhanced workplace safety. They can be integrated into automated assembly lines or used as standalone units, depending on the production requirements. When selecting a fastener insertion machine, factors such as the type and size of fastener, production volume, required accuracy, and budget should be considered to ensure optimal performance and efficiency. Regular maintenance and calibration are also essential to keep the machine operating smoothly and to prevent downtime.

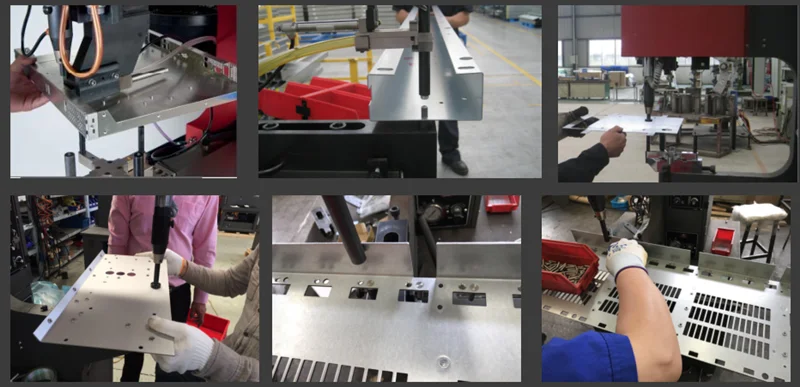

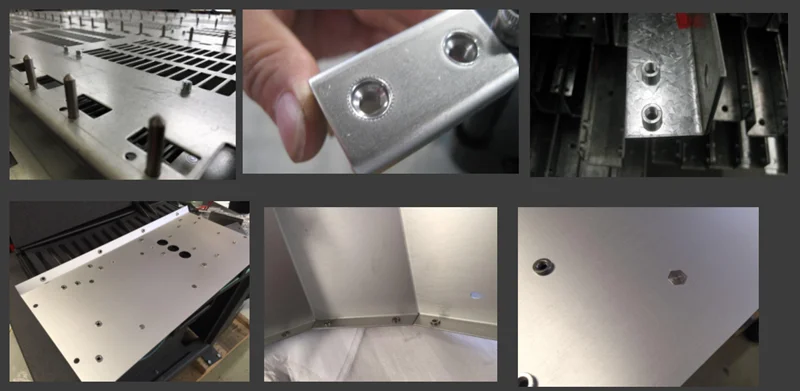

PRODUCT CONFIGURATION

Pressure riveting operating system: The system can realize CAD graphics import programming function and can realize layer hole selection, visual hole position correction function, pressure riveting process parameter self-learning function, pressure data real-time display and traceability system, and product hole position automatic detection function , Product trial processing function. Optional signal connection with robot automatic loading and unloading.

Three visual riveting working modes : ① Three-point MARK working mode : for products with small deformation and incoming hole position accuracy consistent with the drawing ; ② Shoot, press, and work mode : for large deformation and incoming hole positions Products whose accuracy cannot be guaranteed ; ③Visual measurement automatic compensation riveting mode : For products incoming from the same blanking equipment , the actual hole position accuracy is inconsistent with the drawing ;Scope of application : In the riveting state, riveting of product sizes within 800mm*600mm ( multiple products can be placed for simultaneous riveting within the stroke range of small products) can achieve up to 4 different types of rivet riveting; the maximum bending avoidance height of the product 60mm ; the distance from the riveting center hole to the bending edge is ≥ 10mm ; the maximum allowable height difference on the same plane is 30mm . Product change: Select the automatic tools and workpiece tooling plates corresponding to the type of pressure rivets according to product needs, and import CAD graphics for programming .Graphic input programming; visual correction; eliminating mistakes and missing rivets .the machine is user-friendly, the human-machine interface is simple and easy to operate, the pressure, position and speed can be set arbitrarily on the computer screen, and the stroke is adjustable .It adopts all-electric servo pressure riveting, real-time feedback from the pressure sensor, closed-loop pressure control, and high pressure accuracy, which can meet the process requirements of different materials.

Programmable , the program can set the 4- station pressure, holding time, and number of fasteners.

uBuilt-in counter , can count pieces, export online ( U disk copy) alarm information, riveting time, riveting force, production

data, etc.uThe program software can store up to 1 million riveting programs .

greatly improves production efficiency, enables continuous and stable riveting operations, reduces manual intervention, increasesproduction speed, ensures product quality, and meets diversified production needs .Easy to learn and use, flexible production, you can learn programming in 10 minutes and complete product changeover in half an hour .